What we’ve achieved so far

- 24% less residual waste in 2023 compared with 2022

- 12 kilometres of plastic wrap saved per day with reusable pallet boxes

- 25% less air in packaging compared with 2019

Our goal: zero waste by 2040

In a circular economy, there is no waste. Everything we use must last as long as possible or be repurposed. Our goal? Zero waste by 2040 – which means we’ll have no residual waste. We will process all waste streams – through repair, reuse or recycling – in a circular manner. That’s important because burning waste releases a lot of carbon dioxide.

An ambitious goal, but we’re taking steps every year to achieve it. In 2022, our residual waste averaged 53%. By the end of 2023, we had already reduced this to 29% through better separating our waste and thus reducing the amount of residual waste. For 2024, we aim to further reduce the residual waste percentage to 22%.

A second life for our cargo bikes

After 4 or 5 years of use, we assess whether our cargo bikes can be refurbished. We look at which parts we can replace instead of scrapping the entire cargo bike. As a result, there are already more than 150 cargo bikes in use that are expected to last at least another 7 to 8 years. Not only do we extend the lifespan by 2 to 5 years, but it also costs only a third of the price of a new cargo bike.

Reusable packaging for less cardboard waste

We aim to use as little packaging material as possible. We therefore look for ways to waste the least cardboard we can. In collaboration with Bol, we’ve conducted research into reusable packaging. This allows you to easily return a package to the online shop using the same packaging. In doing so, we aim to reduce the amount of packaging and make online shopping less burdensome on the environment.

Coffee from recyclable cups

“I believe in a circular economy where we consume less and focus more on exchanging, repairing, and buying second-hand. This requires a significant transformation of the entire e-commerce sector. Working together is crucial for success in this effort.”

Suzanne Debrichy, Strategic Lead Environment

Together, towards a circular economy

In a circular economy, everyone participates and every step counts. We want to make it as easy as possible for everyone to contribute. For example, our delivery people collect clothing and electronics from our customers for recycling. And through our collaboration with dobbi and the Salvation Army, you can donate or have your clothing repaired at our 800 PostNL locations. This way, we work together towards a circular economy.

Reusable roll container bags

The many parcels that arrive daily at our international sorting centre must be stored safely. Previously, we used roll containers wrapped in plastic, which was a considerable waste of material. Together with our supplier and our people in the sorting centre, we designed a bag with a zipper for the roll container. This saves us 7 kilometres of plastic every day, which amounts to 21,000 kilograms per year.

Our company clothing

Every day, thousands of our delivery people go out in their distinctive orange uniforms. But producing so much company clothing uses a lot of resources and causes carbon emissions. That’s why we’re gradually making our company clothing less harmful to the environment. For example, our orange polos and our new outerwear are made from organic cotton and recycled polyester. Plus, they’re packaged in a wrapper made of recycled paper, and they’re folded in such a way that no separate packaging is needed for shipment.

Circular purchasing

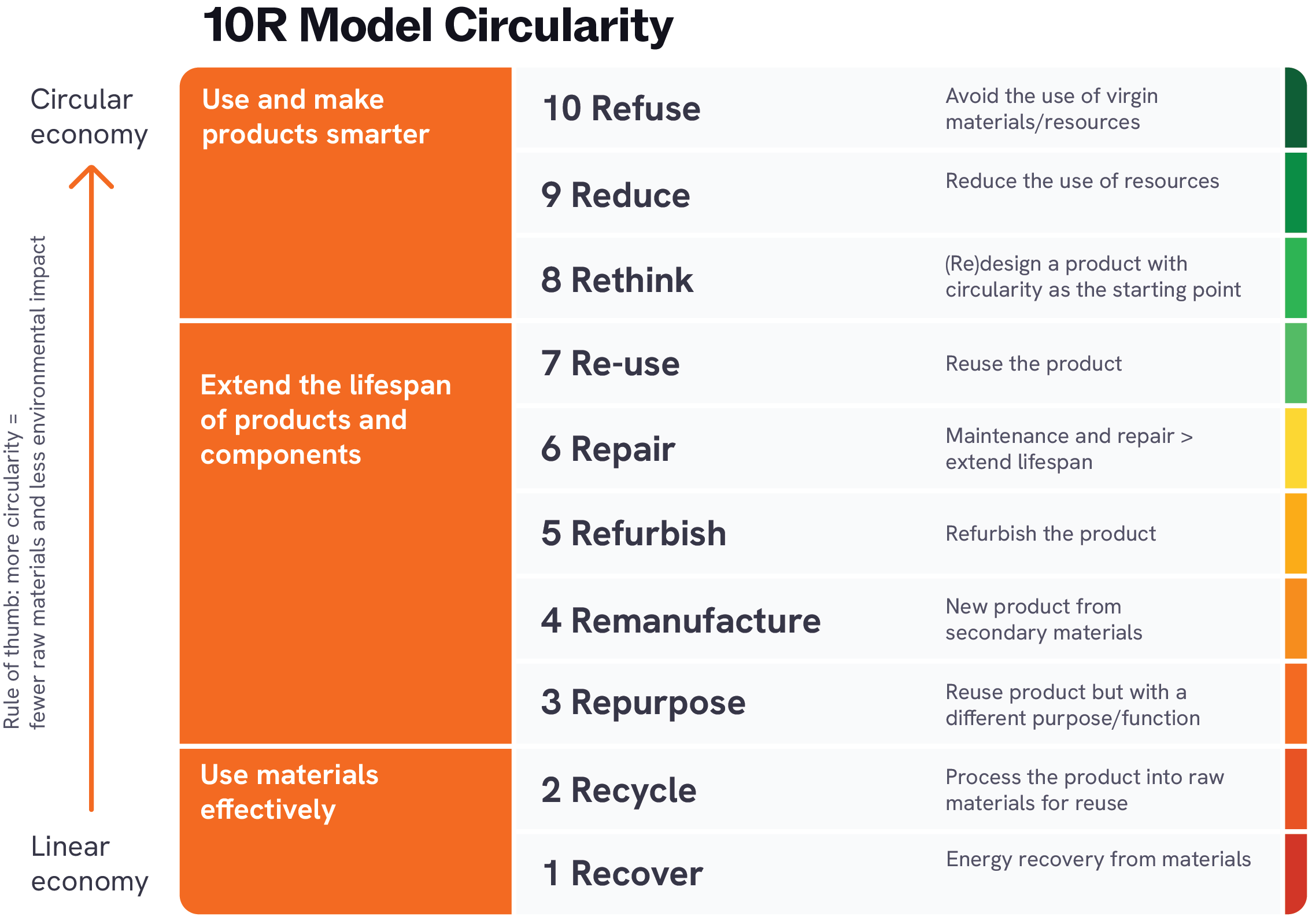

We want to purchase our goods and services with as little impact on the environment as possible, following the rules of the circular economy and the 10R circularity ladder. We therefore adhere to a number of principles:

- The longest possible lifespan of products

- The least (types of) waste possible at the end of a product's or service's lifespan

- The reuse of products is encouraged

Partnership for less residual waste

To separate our waste as effectively as possible, we work together with a waste partner. They help by mapping our many waste streams and our waste processing via a waste scan. This allows us to see where we can still achieve gains in waste separation, thereby reducing our carbon emissions.

How we collect waste more efficiently at our locations

- 1

Identifying improvement opportunities

At our large locations, our waste partner first conducts a waste scan to identify where we can still achieve gains in waste separation. One of the opportunities identified was to install a polystyrene press at our Extra@home locations. This has halved the number of loads needed to transport polystyrene waste.

- 2

Tailoring waste collection

We ensure that the method of waste collection at our locations matches the quantities per type of waste. For example, paper, cardboard, transparent foil and polystyrene. We place press containers at locations with large volumes of waste, allowing us to collect it more efficiently.

- 3

Encouraging waste separation

When making significant changes in our waste collection process, we inform all employees at the location during a kick-off. We also appoint ambassadors who further promote the importance of waste separation. We make it as easy as possible for our employees with clear stickers on the containers. - 4

Monitoring and evaluation

We continuously monitor whether our employees are properly separating waste. The process manager checks this, and discusses it in work meetings at the location. Every quarter, we review the results together. We then assess whether improvements are needed in the process or the behaviour of employees.

More about our sustainability approach

Climate

How do we reduce our emissions in everything we do? That’s our challenge for the future, and we gladly accept it. We’ve therefore set ourselves the goal of reaching net-zero by 2040, with almost no negative impact on the climate.

Liveability

We’re aware of the impact we have on your neighbourhood. That’s why we aim to deliver with minimal impact on the living environment, protecting nature as much as possible in the process.